Flawless Bonding Starts with Flawless Glass.

UV bonding produces an elegant, cohesive appearance for most retail display applications—even when multiple pieces of glass are necessary. Unlike silicone, which can be sloppy and visible when dry, properly UV-bonded glass results in pristine edgework invisible even to the naked eye.

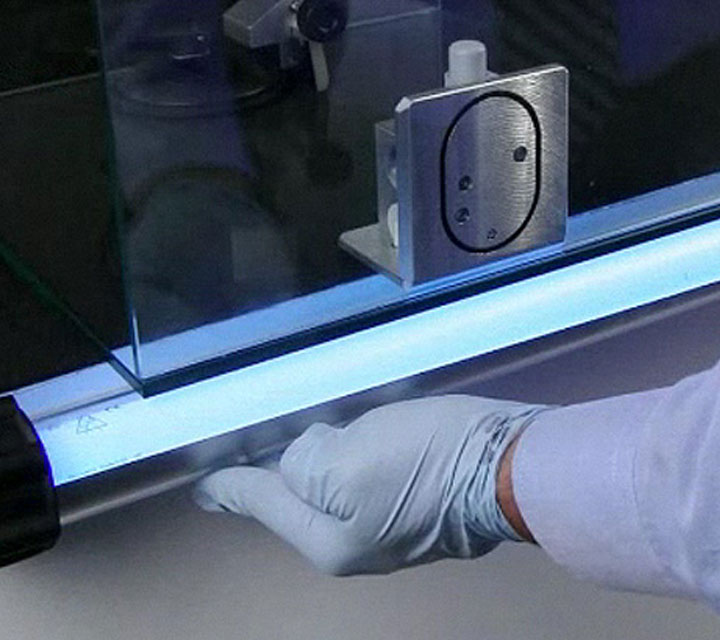

With tighter tolerances and technologically advanced edgework, we eliminate the risk of square edges, overhangs, and inconsistent bonds. Achieved through specialized equipment operated by our Bohle-certified UV glass bonding experts, we’ll ensure your projects are finished with minimally visible, flawless lines.

Security Features to Prevent Damaging “Smash-and-Grab” Crimes

UV-bonded display cases also provide protection from “smash-and-grab” crimes. Typically involving high-end merchandise, these are both dangerous and costly for retailers. Dillmeier Glass Company offers options to reduce these risks through a proprietary in-house solution. Featuring laminated safety glass, this special interlayer process helps deter these incidents, while upholding optical transparency that can be otherwise hindered by dust particles, contamination, and other difficult-to-clean substances.

Learn how Dillmeier Glass Company and iCON Architecture + Fabrication developed a proprietary solution to keep in-store theft at bay, while also eliminating breakage during transport.

Specialized “Clean Room” Environments for Added Productivity

Whether your project requires UV bonding for glass to glass or glass to metal, consider working with a fabricator boasting a climate-controlled, clean room for a pollution-free setting.

From choosing materials to surface preparation, adhesive selection and application, to the final UV curing stages and shipment, your project will be handled with the highest levels of skill and safety.