Precision Edgework & Polishing Capabilities

From pencil and flat polished to mitered and beveled edges, our skilled operators and advanced equipment ensure perfect edgework on every glass piece.

GLASS TEMPERING FOR ADDED SAFETY, STRENGTH & DURABILITY

A Finished, Cohesive Look for Any Application

Whether your project includes frameless glass walls, display cases, railings, tabletops, or doors, complete your look with finishing touches offered through custom edgework and polishing for a timeless, elegant presentation within various spaces and applications.

Avoid Install Challenges With Our Professional Expertise

With correct edgework critical to complement the use of your glass, we’ll partner with you every step of the way to deliver perfect form and fit. Because certain edgwork might not be conducive to your project, you can eliminate concerning install challenges through our technical expertise—we’ve seen it all! Let our experienced engineers review drawings and hardware as even slight modifications to arrisies can avoid incurring extra time and money at point of install.

Beauty & Transparency With Safety Measures in Mind

Aside from added style and character, edging and polishing facilitate easy cleaning and maintenance efforts on your glass surfaces. These fabrication capabilities also boast safety measures to prevent potential injuries from chipping and jagged corners.

For high-end retailers utilizing glass shelves, tabletops, and display cases, or offices looking to create a sense of privacy with glass dividers and partitions, and frameless glass walls—even the slightest enhancements can be a differentiator.

Learn how Dillmeier Glass Company assisted Synergy Business Environments with a flat-polished edge glass divider project for a large healthcare company.

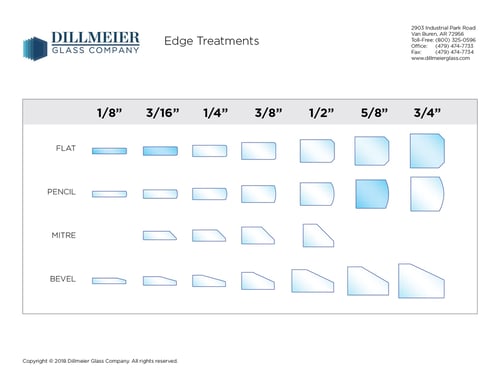

Choose From Various Edging & Polishing Solutions

Learn more about each of the custom options for your project with accompanying, suitable applications.

Pencil Polished

Best for shelving and exposed edges where a rounded profile is preferred, pencil polished finishes create a smooth, rounded edge protecting against potential injuries associated with sharper edges and corners. A standard pencil polished edge will have a glossy or highly polished appearance.

Pencil Satin

With a similar rounded profile as pencil polish, its matte or satin-type sheen make pencil satin the perfect choice when a frosted edge is preferred.

Flat Polished

Unlike pencil polish which is rounded, a flat polished edge features a flat surface surrounded by a top and bottom small chamfer eliminating sharp edges. A standard flat polished edge will appear glossy and highly polished.

Flat Satin

A flat satin edge is a smooth matte or satin finish. It will appear frosted, not highly polished.

Seamed

Also known as cut and swipe, this process removes sharp edges with a sanding belt. Seamed edges are commonly used when all edge surfaces are captured, such as in a wood or metal channel.

Miter

Offered at various angles up to 60 degrees, a mitered edge is typically used to create a corner by marrying two glass edges together. This type of mitered edge is most common in UV-bonded cases, or to create a uniquel aesthetic when working with thicker glass.