Mitered or Flat Edgework: Which Is Best for Your Frameless Glass Case?

When fabricating a frameless glass display case, choosing the right edge type is critical to form and function.

When fabricating a frameless glass display case, choosing the right edge type is critical to form and function.

Also known as UV-bonded cases, these are traditionally utilized across various industries to showcase any number of items, from high-end jewelry and watches to foodstuffs and antiques—the list goes on and on. Such displays help retailers highlight specific products and boost visibility among consumers.

Presentation matters a lot to patrons, enhancing their overall experience—which ideally results in more sales.

“More than half (54%) of retailers said the customer experience is their most important area of focus,” states a 2018 analysis of retail marketing and consumer shopping trends by customer retention and acquisition solutions provider V12.

Two popular edge styles of frameless glass display cases are flat and mitered. This useful explainer outlines the benefits of both, and provides insights about the fabrication process, to help you choose the best for your project or business.

Low-iron glass, unlike clear glass, is the most transparent.

UV Bonding

Frameless display cases consist of multiple pieces of glass joined together with a special glue cured under ultraviolet light. The final product appears nearly seamless, and low-iron glass provides the most transparency.

Choosing an Edge Type

Once your low-iron glass is cut, it’s best to work with a fabricator, such as Dillmeier Glass, to provide guidance on the best edge.

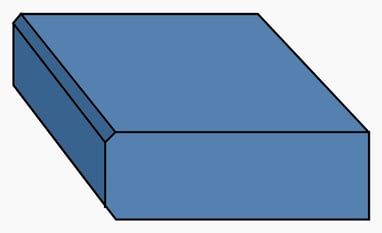

Flat Edge

Flat edges, which are smooth and linear, consist of two common types: polished and satin.

Flat Polished

During the fabrication process, the glass moves along a conveyor belt, which removes chips to create a smooth, glossy appearance that's optimal for vitrines. The thicker the glass, the sturdier the final display case.

Flat Satin

Unlike the aforementioned flat-polished, this edge conveys a satiny appearance. It's useful for a mirrored, decorative look.

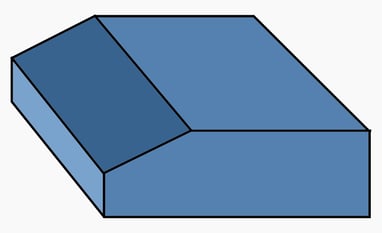

Mitered Edge

Glass pieces with mitered edges are joined at right angles and create a more unified, flawless design. This makes the exhibited objects the true focal points of the display cases.

Fabrication demands specialized equipment and knowledgeable experts—resulting in slightly higher costs than flat edgework.

Consult A Professional

It’s best to consult with a professional glass fabricator, such as Dillmeier Glass, when deciding on edges. Our team specializes in fabricating seamless, secure, and elegantly edged frameless glass display cases for any business or project. We’ve even devised a customized process to strengthen the glass and thwart so-called “smash and grab” crimes.

Contact us today to determine which edge type is best for your frameless glass display.