Glass Edge Types: Which Is Best for Your Project?

Editor’s Note: This blog post was originally published in February 2020 and has been revised to reflect industry updates.

When it comes to glass fabrication processes, one of the most important is edging. Creating a sophisticated, finished look, it’s often incorporated into conference tables, partitions, dividers and doors, markerboards, and display cases in a vast array of retail, hospitality, and office environments.

Glass edging adds style and character. It’s also easy to clean and maintain. Regardless of industry, custom edgework is additionally utilized to help prevent injuries from chipped or jagged glass corners. Choosing the best type is determined by several factors and considerations, such as the fabrication project, and intended application and usage.

Below we’ll discuss the glass edging process, review several types, and address why some are more appropriate for specific applications than others.

What Is Glass Edging?

Glass edging is the fabrication process of grinding and shaping raw, jagged glass corners into a smooth, finished texture. It is highly specialized, and best handled by an experienced fabricator with professional equipment and operators, such as Dillmeier Glass Company.

Glass Edging Benefits

To achieve added beauty and elegance for any fabrication project, glass edging also offers several invaluable safety and durability advantages, such as smooth edges, resistance to chipping, and increased strength.

Edging can also prevent possible injuries and other dangers from untreated glass.

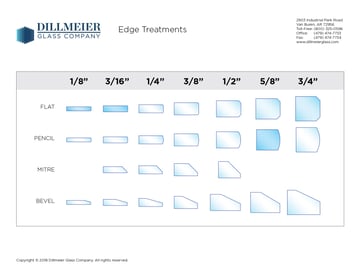

Learn more about each custom edging type offered by Dillmeier Glass Company, as well as accompanying applications:

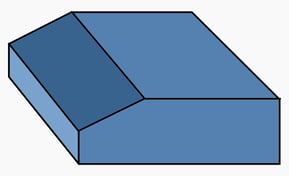

Pencil-Polished Edge

Its name derived from the rounded, smooth finish of a pencil, this edge is used for tabletops and other furniture requiring glass protectors.

Its name derived from the rounded, smooth finish of a pencil, this edge is used for tabletops and other furniture requiring glass protectors.

This polished texture can be utilized on additional furniture and fixtures, such as mirrors, frames, and shelves. It also protects against potential injuries associated with otherwise sharp and abrasive corners.

When considering this edge for a large project with short lead time, it’s best to enlist a glass fabricator with advanced equipment. This will further ensure it’s delivered on time, without sacrificing quality.

Applications

- Furniture

- Mirrors

- Frames

- Shelves

- Display Cases

Pencil Satin Edge

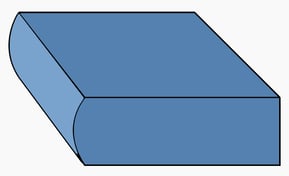

Also referred to as pencil-grind or semi-polished, this rounded edge derives its name from its pencil-like shape.

Also referred to as pencil-grind or semi-polished, this rounded edge derives its name from its pencil-like shape.

Created by a diamond-embedded grinding wheel, a pencil-ground edge—unlike the glossy finish appearance of pencil-polish edges—exudes a matte or satin-type sheen, making it perfect for light-color surfaces, mirrors, and decorative glass furniture.

Applications

-

Light-Color or Transparent Surfaces

-

Mirrors

-

Decorative Glass Furniture

Flat-Polished Edge

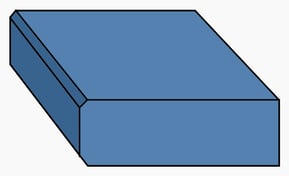

Also known as flat edge or machine-polished edge, this features sleek, clean, and glossy lines from running along a belt machine, removing any chips, and smoothing edges. A flat-polished edge achieves a finished look for display purposes, such as mirrors, retail cases, glass dividers, and other decorative furniture. Flat polish appears thicker due to its refined, simplistic characteristics—and is typically used for 1/4-inch glass or thicker.

Also known as flat edge or machine-polished edge, this features sleek, clean, and glossy lines from running along a belt machine, removing any chips, and smoothing edges. A flat-polished edge achieves a finished look for display purposes, such as mirrors, retail cases, glass dividers, and other decorative furniture. Flat polish appears thicker due to its refined, simplistic characteristics—and is typically used for 1/4-inch glass or thicker.

Specialized, high-quality, flat-polishing equipment is required. Such machines can buff any glass size and shape, even with strict lead times, regardless of thickness.

The chamfer—where the flat polished edge meets the glass surface—can be arrised, or smooth and angled, as noted in the accompanying illustration.

Applications

-

Mirrors

-

Retail Display Cases

-

Glass Dividers & Partitions

-

Decorative Furniture

To learn how Dillmeier Glass Company assisted a large healthcare company with a flat-polished edge glass divider project, check out:

![]()

“Dillmeier Glass Company Helps Synergy Business Environments Save the Day”

Flat Satin

Except for its flat appearance, this is similar to the pencil satin edge. It, too, boasts a satin-like sheen, making it appropriate for mirrors and decorative glass furniture.

Applications

-

Mirrors

-

Decorative Glass Furniture

Beveled Edge

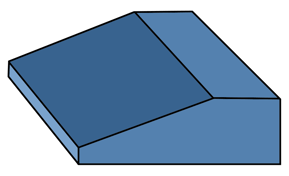

Also known as sloped or chamfered edge, this is flat and grinded for smoothness. Bevels are achieved by cutting and polishing the edges for a distinctly elegant look—thinner along the sides and thicker at its center.

Also known as sloped or chamfered edge, this is flat and grinded for smoothness. Bevels are achieved by cutting and polishing the edges for a distinctly elegant look—thinner along the sides and thicker at its center.

Such edgework adds depth and opulence. Beveled edges are shiny and glossy, presenting a finished, polished look. Similar to the pencil-polished style, beveled-edged glass is also suited for decorative pieces such as mirrors.

Applications

-

Mirrors

-

Other Decorative Glass Solutions

Miter Edge

Also known as a slanted edge beveled anywhere up to a 60 degrees, this connects two pieces of glass in a specific angle. Without this, the glass would butt up, rather than smoothly conjoin. A miter edge can also be utilized as a stand-alone application for silicone structural glazing, or to create a uniquely visual aesthetic with thicker glass.

Applications

-

Retail Display Cases

-

Glass Shelving

-

Any Setting Requiring Thick Glass

Seamed Edge

This is created with a sanding belt, and also known as cut and swipe. Because they don’t feature smooth or complete finishes, seamed edges are often utilized if unexposed or concealed.

Applications

-

Framed Glass Walls & Partitions

-

Any Non-Decorative Solution

-

Low-Traffic Areas

Glass Edging & Design Changes

Edging can help redefine and stylize retail store display cases and shelves for upselling and other special promotions. Hospitality-based settings, such as restaurants and lounges with revised indoor and outdoor seating plans could also benefit from edging. These include glass tabletops and bars, and other service areas.

With more and more on-site employees returning to offices, glass dividers, partitions, and frameless glass walls can also be edged. Choosing the best type is determined by a workplace’s floor plan, layout, social-distancing requirements, and other changes.

Determining the Best Solution for Your Project

With several glass edges to choose from, it’s recommended to consult a professional fabricator such as Dillmeier Glass Company. Our experts will utilize the specialized equipment required to customize and complete your project on time and within budget.

Dillmeier Glass Company can assist businesses of many sizes and industries with customized glass edging. Tell us about your project today!